Home > Products >

Briquette Machine >

Twin-roller Machine

Home > Products >

Briquette Machine >

Twin-roller Machine

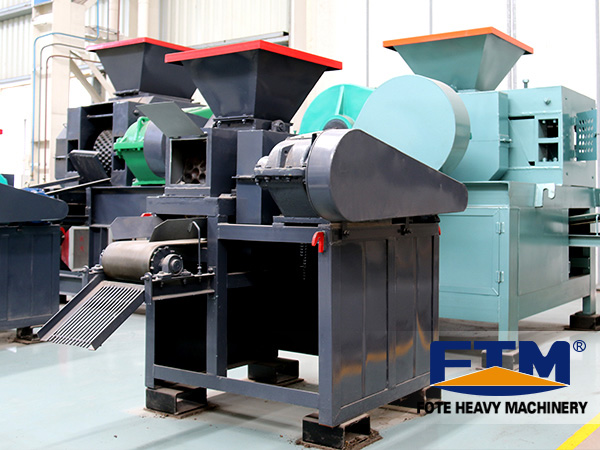

Twin-roller machine or twin roller machine has obvious features such as high ball rate, small power consumption, compact structure,easy to maintain,etc. It is absolutely an ideal key equipment for extraction of magnesium with Pidgeon process.

To satisfy the requirement of material forming,the preload spiral adopts electromagnetic speed regulating motor with manual type to control the speed, the user can based on the ball shaping situation to change the preload machine's rotation speed to achieve the highest ball rate and maximum capacity, pressed materials go through the sieving machine, and qualified pellets on the screen will be packed, while the undersized materials will return to chamber and mix with new materials for second pression.

Twin roller machine is mainly used for surpressing the dry powder into ball pellets in the extraction of magnesium with Pidgeon process.The requests for the shaped materials are as follows:

1. Materials' granularity:80~200 mesh

2. No metal in the materials, or it will damage the surface of the roller

3. Satisfied feeding quantity, adjustable speed of screw feeder should be used to observe the scrap and adjust new materials supply.

1. Feeding parts are mainly used to realize the quantitative feeding to ensure materials uniformly enter the rollers. The spiral feeder is driven by electromagnetic speed regulating motor, rotated by the pulley, worm reducer, and press materials into the main feeder opening.

2. Transmission parts: main drive system: the motor - triangle strip - reducer - open gear - roller.

3. Shaping parts, mainly refers to the host, the core part is the roller.

| Model | Roll diamter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |