Home > Products >

Briquette Machine >

High pressure briquette machine

Home > Products >

Briquette Machine >

High pressure briquette machine

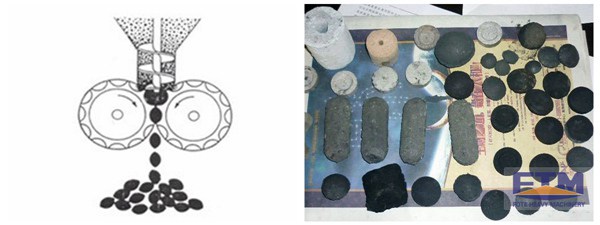

High pressure briquette machine is mainly used to process the difficult molding powdery material. High pressure briquetting machine is characterized by high molding pressure and adjustable host rpm. It is equipped with screw feeding device.

1) Feeding device: it is mainly used to achieve constant feeding to ensure that materials enter the gap between the rollers evenly.

2) Transmission parts: the main transmission system includes motor - triangle belts---reducer --- --open gear ----rollers.

3) Molding part: it mainly refers to the host and the core part is the roller.

High pressure briquetting machine or high pressure briquette machine is mainly used to make the coal powder, iron powder, coke, aluminum powder, scrap iron, sinter, toner, carbon dust, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze and other powders and wastes, which is widely used in refractory, power plants, metallurgy, chemical industry, energy, transport, heating and other industries. The molding materials after the processing of high pressure briquetting machine are energy saving and easy to transport, improving the utilization rate of waste materials and having good economic and social benefits.

| Model | Roll diamter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |