Home > Products >

Briquette Machine >

Energy saving briquette machine

Home > Products >

Briquette Machine >

Energy saving briquette machine

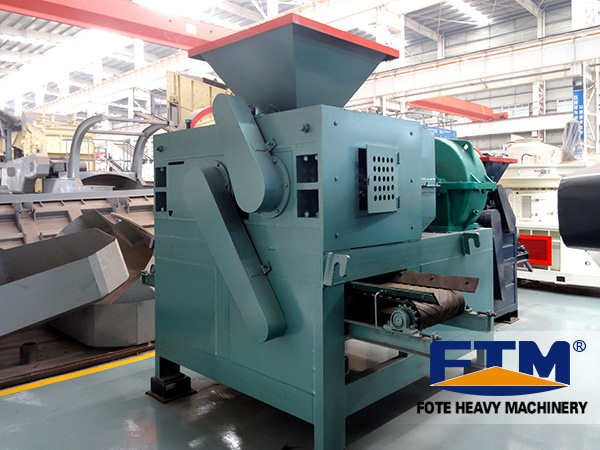

Energy saving briquette machine or energy saving briquetting machine is mainly used to process the difficult molding powdery material and it is characterized by high molding pressure and adjustable host rpm. It is equipped with screw feeding device.

Screw feeding device: it will force the material to be pressed into the main inlet.

Hydraulic protection device: the hydraulic pump will inject the high pressure oil into the hydraulic cylinder to make the piston have axial displacement. The machine can adjust the pressure according to the ball density requirements and the production is flexible.

As for the energy saving briquette machine host, the electromagnetic adjustable-speed motor will provide the power for it and the power will be sent to the driving shaft through the rod coupling via the pulley and cylindrical gear reducer. The open gear will guarantee the synchronous operation of the driving shaft and the driven shaft. Behind the passive bearing pedestal, it is equipped with hydraulic device.

Energy saving briquetting machine is widely used in refractory, power plants, metallurgy, chemical industry, energy, transport, heating and other industries.

| Model | Roll diamter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |