Home > Products >

Briquette Machine >

Mineral powder briquette machine

Home > Products >

Briquette Machine >

Mineral powder briquette machine

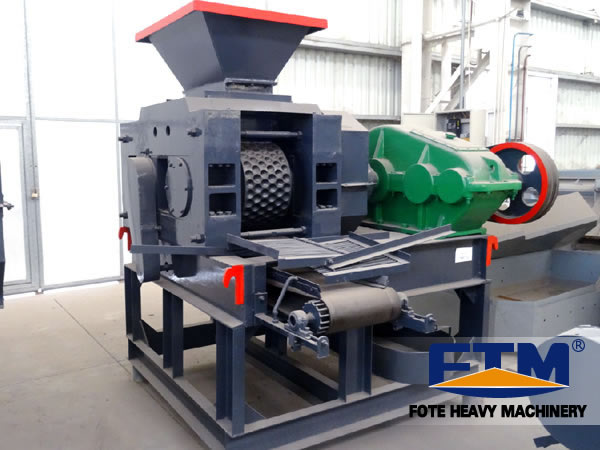

Mineral powder bbriquette machine can be used to suppress coal powder, iron powder, coking coal, Aluminum powder, scrap iron, iron oxide skin, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze and various other powder, powder material, waste and residue, so it’s widely used in resistance material, power plant, metallurgical, chemical, energy, transport, heating and other industry.

Material produced by using mineral powder briquetting machine is energy environmental and easy to transport, which can improve the utilization on waste, and has good statistics and social benefits.

Feeding part is expected to ensure the even feeding of materials into the ball briquetting machine or briquette machine.

Transmission part, with main drive system of motor-triangle-shaped belt------open gear reducer---rolls.

Forming part mainly refers to the host portion, while the hardcore is the roll.

The roll is casted by Manganese, so its hardness is up to 58 degrees after special heat treatment. roller is combined assembly, and wear can be replaced. Mineral powder briquetting machine is designed with buffer mechanism, and the mineral powder briquette machine is designed with adjustable ball so that the two rollers balls are always in the adjustable range. Material uniformly and quantitatively enters forming machine Hopper from storage warehouse, the adjusting gate on the hopper can make material uniformly enter into the middle room of rollers, and then the material will be pressed,and the pressure is from small to large, after materials passing the line in the middle of the two rollers, the forming pressure grows smaller, and the material can well off the ball to complete the whole process.

| Model | Roll diamter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |