Home > Products >

Briquette Machine >

Quicklime briquette machine

Home > Products >

Briquette Machine >

Quicklime briquette machine

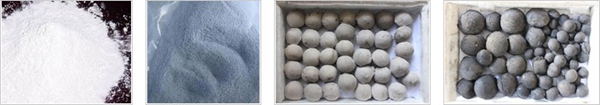

Quicklime briquette machine or lime briquetting machine is mainly used for ball making with waste lime powder. In the usage of the machine, there is the need to control the operation of the device. Quicklime briquette machine or quicklime briquetting machine is easy to operate and has high efficiency, and it is currently recognized by the uses.

Due to the scientific research of the related institutions in metallurgy industry, this problem has been solved, namely, to use the high-pressure quicklime briquetting machine to press the powder into block for smelting.

Quicklime briquette machine or lime briquetting machine is mainly used to make the coal powder, iron powder, coke, aluminum powder, scrap iron, sinter, toner, carbon dust, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke breeze and other powders and wastes, widely used in refractory, power plants, metallurgy, chemical industry, energy, transport, heating and other industries. The molding materials after being processed by quicklime briquette machine or lime briquetting machine are energy saving and easy to transport, improving the utilization rate of waste materials and having good economic and social benefits.

Quicklime briquette machine or lime briquetting machine mainly consists of the host, motor, reducer, transmission device and other components. Its internal part-the roller skin is made of 65 Mn casting and uses the combination assembly so that it can be replaced after being worn. There is buffer device in the ball press machine and it can protect the device from the impact of hard objects.

| Model | Roll diamter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |