Home > Products >

Briquette Machine >

Hydraulic briquette machine

Home > Products >

Briquette Machine >

Hydraulic briquette machine

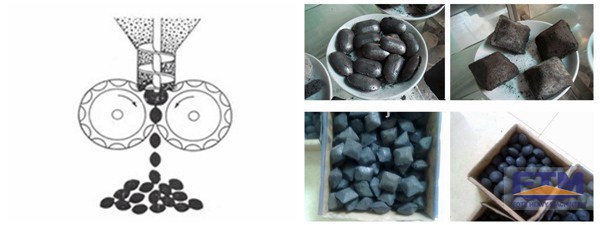

Hydraulic briquette machine or hydraulic briquetting machine can be used for various ore powder, metal powder, coal, coke and other materials.

Because of the mandatory squeeze rollers, the product has high density, high strength and high hardness. Hydraulic briquette making machine adopts 650 mm hardness material to make roller, which has good wear resistance, thus effectively improves the service life of the pressure roller.

Small hydraulic briquetting machine is suitable for various molding of industrial gasification, coal boiler, cold coke, coal fire, civil coal, civil metallurgy, refractory, medicine and other materials.

Materials are added evenly into the molding machine hopper going through quantitative equipment from the storage; under the regulation of hopper adjustment ram ,materials are added evenly between rollers.The molding pressure reaches its maximum at the roll center of the connection and then quickly become smaller, so that materials smoothly take off the ball.

In hydraulic overloading protective device , the high pressure oil is pressed into the hydraulic cylinder through the hydraulic pump, thus the piston makes axial displacement. Front connector of the piston rod is on the bearing pressure to meet production requirements and protect pressure roller from bring damaged.

| Model | Roll diamter (mm) |

Roll width (mm) |

Total pressure (t) |

Main motor power (kw) |

Output (t) |

Weight (t) |

| GY520-150 | 520 | 196 | 150 | 55 | 2.2-3.5 | 13 |

| GY650-220 | 650 | 200 | 220 | 110 | 4-6.5 | 19.2 |

| GY750-300 | 750 | 280 | 300 | 185 | 6-8.5 | 34 |

| GY1000-350 | 1000 | 440 | 350 | 250 | 10-15 | 50.8 |

| GY1000-450 | 1000 | 504 | 450 | 280 | 14-17 | 58.5 |

| GY1000-500 | 1000 | 504 | 500 | 315 | 15-20 | 58.5 |

| GYS1000-500 | 1000 | 600 | 500 | 280 | 17-21 | 56.5 |

| GY1000-540 | 1000 | 900 | 540 | 185Kw×2 | 30-35 | 60 |

| GY1200-800 | 1200 | 900 | 800 | 280Kw×2 | 40 | 110 |

| GY1400-1000 | 1400 | 1000 | 1000 | 400Kw×2 | 50 | 156 |