Home > Products >

Dryer Machine >

Coconut Shell Dryer

Home > Products >

Dryer Machine >

Coconut Shell Dryer

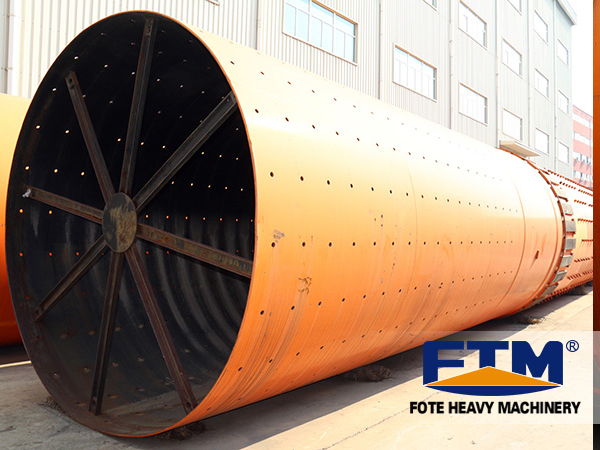

Coconut shell dryer is also called coco shell dryer. Coconut shell dryer is widely used in straw fuel, mechanical, wood pellets, sawdust briquette charcoal, agricultural engineering and other industries.

Fote is a famous coconut shell drying machine manufacturer with high reputation all around the world. The products made in Fote Machinery all have high quality and reasonable price. You can get contact with us to get more detailed information.

Coconut shell dryer is composed of heating furnace, feeding mouth, rotating tube, filter tube, material conveying tube, cooling tube and discharge mouth. Rotating tube is located on the active wheel. Active wheel make the rotary barrel moves in low speed by motor and the deceleration drive. There is feeding mouth between the heating furnace and rotary barrel, and inside the rotary barrel, there are stirring blades. Between the rotary barrel and the filter tube, there is a baffle and there is a hole on the baffle.

One end of the filter tube is connected with rotary barrel and the other end is connected with material conveying tube. Inside the filter tube, there is block and there is slag discharge hole on the bottom of the filter tube. One end of the cooling tube is connected with material conveying machine by the air blower and the other end of the cooling tube is connected with the discharge mouth.

By using the structure, the waste coconut shell can dry fully in rotating cylinder, and coconut shell waste can fully spread again before into the material conveying pipe to make moisture evaporate faster. The block can block the impurities in waste coconut shell to ensure quality of coconut waste which is into the material conveying pipe. When coconut shell waste into the dryer, it processed by interaction of injection tube and rotating cylinder. The material boils and fluidifies in the tube and the material has full access to the hot blast to complete drying.

1. High dry intensity. The material highly disperses in the air flow, the whole surface of the material are all effective drying surface.

2. Short drying time

3. Air dryer has simple structure, covers little space and easy to build and maintain.

4. Large capacity and high thermal efficiency. When drying unbound water, the thermal efficiency can reach 60%

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |