Home > Products >

Production Lines >

Mobile impact crusher

Home > Products >

Production Lines >

Mobile impact crusher

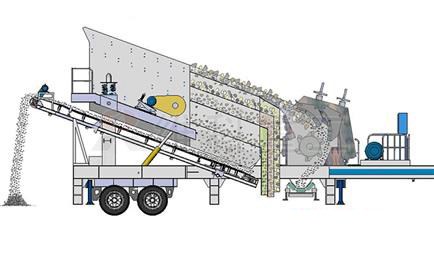

mobile impact crusher is also called tracked impact crushing plant or track mounted impact crusher. Tracked impact crusher adopts advanced technology and high quality high-chromium plate and wear-resistant impact lining plate. It has large crushing ratio. And the advantage of perfect product quality makes it very popular among the customers.

Tracked impact crusher is often used as the secondary crushing machine. It is usually used in metallurgy, chemical industry, building materials, water and electricity frequent relocation work in materials processing, especially for motorway ,stone railway, hydropower and other liquidity operations.

1. It is widely used in mining, coal mining, garbage and recycling of construction waste, earth works and urban infrastructure, roads or building sites and other ground operations.

2. Process topsoil and a variety of other materials; isolated viscous concrete aggregate; construction and demolition industries; broken screen; and quarrying industry.

3. River pebbles, rocks (limestone, granite, basalt, diabase, andesite), ore tailings and the artificial sand stone chips.

1. Flexible configuration of equipment, single-unit independent production. Tracked impact crusher can also be used with other equipment.

2. Small turning radius, easily broken field rugged driving in bad road conditions, more conducive to the presence in the construction areas.

3. Configuration of inversed impact crusher can conduct on-site crushing of certain line items, direct outputs ideal particle size of aggregate products, scope of work extend also reduces the transfer of material and shipping costs. Furthermore tracked impact crusher can directly convert broken materials into a transfer vehicle tank, convenient and timely transportation.

4. Great product particle size and high working efficiency.

5. Tracked impact crusher installed in integration and overall coordination, and spatial layout is compact which can save time and space for on-site construction and increase flexibility. Meanwhile, it eliminates a lot of infrastructure, significantly reducing investment costs, so it is convenient operation and maintenance. Unit equipment Division of labor is clear concise and easy to maintain.

| Model | FTM938F1210 | FTM938F1214 | FTM1149F1315 | FTM1349F1110 | FTM1349F1315 |

| Transportation Length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Crusher Model | PF-1210 | PF-1214 | PF-1315 | HD1110 | HD1315 |

| The Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Production Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(Optional) | B500×3.2M | B500×3.2M | B650×4M | B650×4M | B650×4M |

| Genset(Optional) (kw) | 320 | 320 | 400 | 320 | 440 |

| Iron Separator (Optional)(kw) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |